Full - process control

Precision Batching

The ERP system ensures precise strip's thickness and formulation

Process Control

Control and analysis of magnetic powder particle size and distribution

Performance Testing

Blank parts' dimension, magnetization direction, magnetic flux lines

Pre-shipping Inspection

Dimensions and tolerances, appearance, magnetic properties, coating thickness, corrosion resistance and coating adhesion

Testing Equipment

Equipped with first-class testing and experimental facilities, and staffed by professionals with years of industry experience, we strictly control the management of incoming material inspection, in-process inspection, and outgoing quality control. This integrated management of the production process ensures stable product quality and excellent customer service.

Carbon Sulfur Analyzer

In the production of NdFeB magnets, the content of carbon (C) and sulfur (S) in raw materials significantly impacts the product's magnetic properties, corrosion resistance, and mechanical strength. Our carbon sulfur analyzer uses advanced detection technology to quickly and accurately measure carbon and sulfur content in materials, precisely monitoring carbon and sulfur impurities.

Oxygen Nitrogen Hydrogen Analyzer

The content of gaseous elements such as oxygen (O), nitrogen (N), and hydrogen (H) directly affects the magnetic properties, oxidation resistance, and structural stability of NdFeB magnets. The oxygen nitrogen hydrogen analyzer employs internationally advanced detection technology to strictly control oxygen content, prevent degradation of magnetic properties, monitor hydrogen content to avoid hydrogen embrittlement, and control nitrogen content to ensure material stability.

Ultra-Precision Permanent Magnet Auto-Tester

Accurate measurement of magnetic properties is crucial for ensuring magnet product quality. Our high-end automatic permanent magnet characteristic measuring instrument can fully automatically and high-precision measure core parameters of magnets such as **magnetic hysteresis loop (B-H curve), remanence (Br), coercive force (Hcb/Hcj), maximum energy product (BHmax). Fully automated operation reduces human error and improves detection speed, ensuring professionalism and reliability.

Keyence Image Dimension Projector

Keyence's image dimension projectors (such as IM series or VH series) are optical measuring devices for high-precision dimension measurement, capable of measuring geometric parameters of magnets such as length, width, height, diameter, angle, and roundness, with a resolution typically reaching ±1μm level to meet the high tolerance requirements of NdFeB magnets. The automatic edge detection function quickly and accurately identifies magnet boundaries, reducing human error.

Magnetic Ring Automatic Flaw Detector

In the production of NdFeB magnetic rings, we use automatic magnetic ring flaw detectors (typically based on eddy current, magnetic particle, or optical principles) to detect internal and surface defects of magnetic rings, with rotating probes or annular sensors providing full coverage inspection of the inner and outer walls of magnetic rings (such as eddy current flaw detection).

CCD Appearance Dimension Full Inspection Machine

Based on high-resolution industrial cameras + image processing technology, it achieves automated detection of magnet appearance defects and dimensions. Efficiently and automatically detects surface defects of magnets: such as cracks, scratches, chipping, pores, coating blisters (e.g., nickel/zinc/epoxy coatings). Appearance flaws: stains, color differences, oxidation spots, uneven coating. Geometric defects: deformation, edge burrs, incomplete chamfers.

Magnetic Flux Full Inspection Machine

Quickly and accurately measures key parameters such as magnetic flux and magnetic moment of magnets; suitable for different shapes of magnets such as blocks, cylinders, rings, and sectors; 100% full inspection replaces sampling inspection, solving problems of low efficiency and poor consistency in manual sampling inspection.

Magnetic Declination Detector

The accuracy of the magnet's magnetization direction directly affects product performance and stability. Our high-end magnetic declination detection equipment is designed to precisely measure the deviation of the magnet's magnetization direction (magnetic declination), ensuring that each magnet meets strict magnetic orientation standards and ensuring more accurate and reliable product performance.

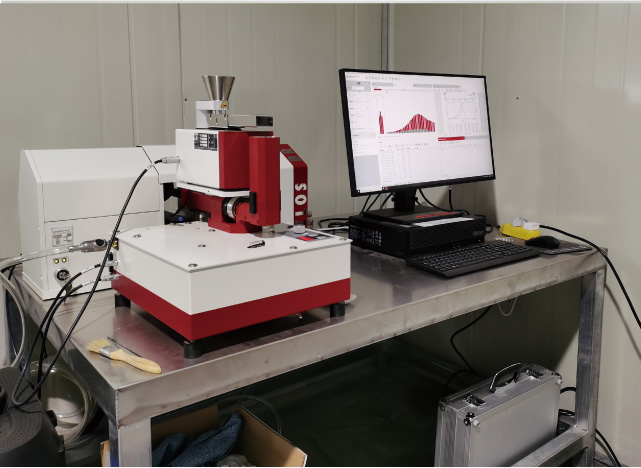

Laser Particle Size Analyzer

A precision instrument for measuring particle size distribution, leveraging laser diffraction principle to rapidly and accurately analyze particle size distribution. After hydrogen crushing, neodymium-iron-boron alloy ingots form coarse powder, which requires further refinement by jet milling. The laser particle size analyzer monitors real-time particle size distribution (D50, D90) of the crushed powder, ensuring it reaches single-domain size (typically 3-5 μm), crucial for high coercivity. It quickly detects submicron fine powder proportion to adjust jet mill parameters promptly.